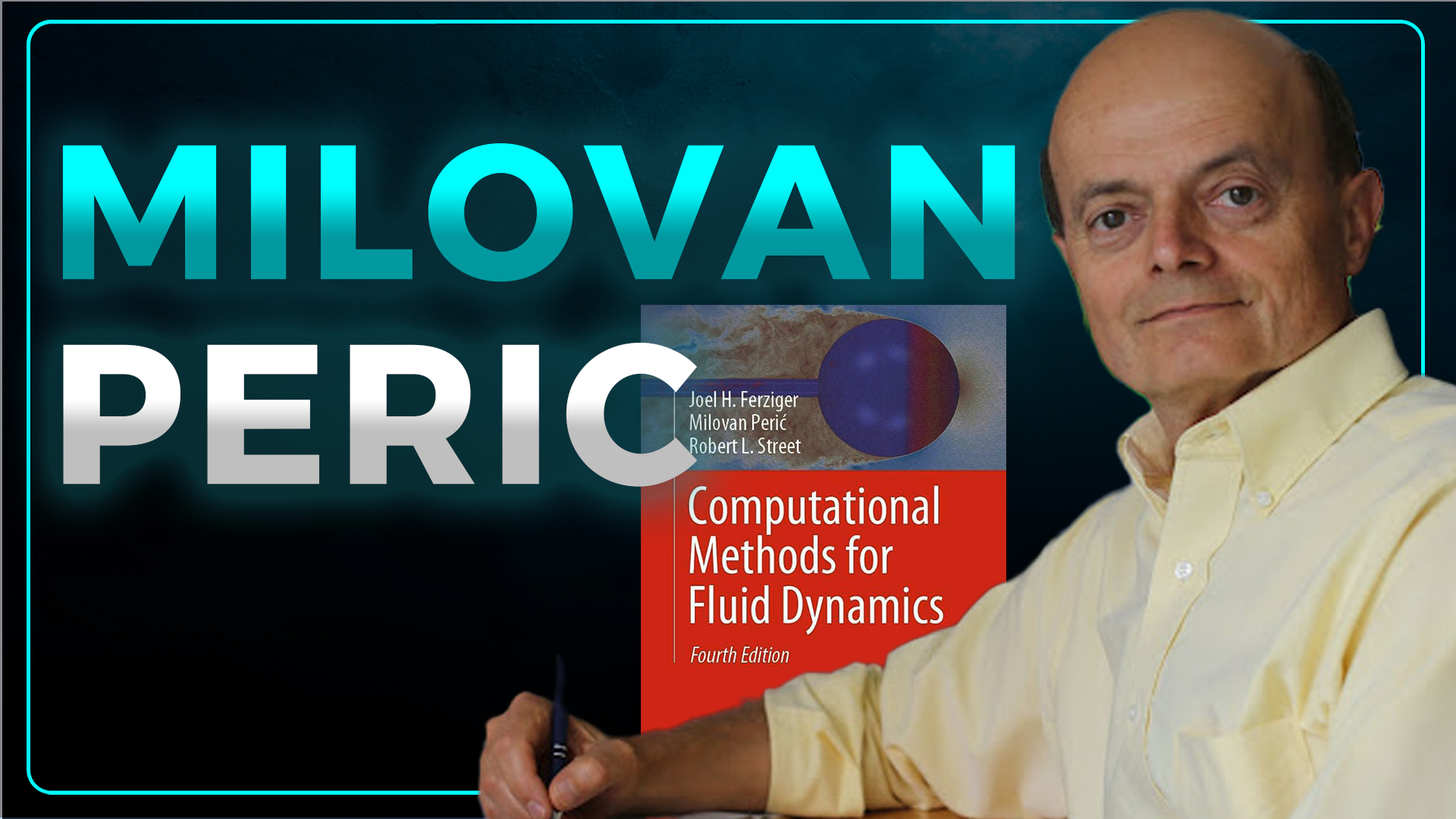

Explore the engineering world in our interview with Milovan Peric, where he shares valuable insights into his life and work as a leading expert in Computational Fluid Dynamics. Don't miss this opportunity to learn from one of the brightest minds in the field!

Bio 🌱

Milovan Peric is a dedicated engineer who has dreamed of working in the field since he was six. Ten years ago, he was the Vice President for Technology at CD-adapco, a company known for its CFD (Computational Fluid Dynamics) software, STAR-CCM+. In this role, he reported to the CEO, Steve MacDonald, and helped lead a team of over 800 employees. He shifted from full-time work to consulting due to the extensive travel demands, which kept him away from home for over half the year.

Since 2014, Milovan has worked as an engineering consultant, mainly for CD-adapco and later Siemens, which acquired the company in 2016. He has also consulted for other companies in Germany and taught Applied CFD at the University of Duisburg-Essen. As he plans to retire at the end of the year, Milovan is winding down his teaching and consulting roles but continues to pursue his passion for CFD on his terms.

He is working with Professor Bob Street on the fifth English edition of their book, "Computational Methods for Fluid Dynamics," and will start publishing his work on CFD on the website for book readers: www.cfd-peric.de. Sponsored by Siemens, Milovan is also working on two YouTube video series on CFD, offering free lectures, presentations, and additional resources for students and teachers.

As he wraps up these projects, Milovan is considering future work that might involve improving current CFD techniques or exploring new, advanced methods.

Links 🔗

🌍 Website: http://www.cfd-peric.de

📚 The Perić lectures on CFD: https://sie.ag/6a3r6J

Q&A 🗣️ - Why CFD? 🌀

I “decided” to become an engineer at the age of 6, i.e. in 1963. Still, CFD was not on my radar until the time came to do a project for my diploma thesis in the final year of my studies in mechanical engineering at the University of Sarajevo. Professor Pavle Kaludjerčić offered me an advanced topic – to simulate flow, heat, and mass transfer in an evaporative air-conditioning chamber. It was a one-dimensional analysis, but I still consider it as a proper CFD because I have had to solve the same conservation equations that CFD tools solve today – only in one dimension.

That work was published in a German journal – my first publication. It was very exciting for me, and at the same time fascinating to see a reasonably good agreement between simulation and experimental data from the literature. At that time, I recognized the power of conservation equations and admired people like Navier and Stokes who created those equations at a time when they had no chance of solving them and proving that they work in real-life applications. They could only prove that equations produce correct solutions in a handful of flows under conditions that highly simplify the equations, because most terms become zero and drop out, like in fully developed flows in channels and pipes.

After graduating in July 1980, it was still not clear to me that I would be doing CFD for the rest of my life. However, I did want to do research, but it could have equally been of an experimental nature, because I liked doing experiments as well. The motivation for the research came from my first conference attendance. During my work on the diploma project, Professor Kaludjerčić took me with him to attend the congress on air-conditioning, heating, and cooling in Belgrade. He covered all the costs of one of his projects and I’ll never forget that generosity. At the congress, Professor Bošnjaković, from whose books I learned thermodynamics, gave a lecture on heat pumps. Heat pumps are today installed in almost every new house, but back in 1979, the principles of their work were a research topic. That lecture made a huge impression on me. Professor Bošnjaković worked as a young researcher with Mollier in Germany before the 2nd World War (remember Mollier’s diagram for humid air – enthalpy against relative humidity?) and was a professor at the University of Stuttgart after the war. For me listening to his lecture was the greatest event in my life until then…

I wanted to go to the USA to do research in something related to fluid flow, heat, and mass transfer. I applied for a Fulbright scholarship but unfortunately did not get it. And then, Ismet Demirdžić contacted me from London. He was doing PhD with Professor David Gosman, just about to finish his thesis, and he asked me whether I would like to come and continue his work. Professor Gosman was very happy with his performance and asked whether there were more people like him in Sarajevo; he thought of me and said yes… I did not have to think twice and said yes, too, and a few months later I was at Imperial College in London. That cemented me in CFD for the rest of my life…

Your First Job 💼

My first proper job was as a post-doc at the Chair for Fluid Dynamics, University of Erlangen, Germany, led by Professor Franz Durst. I was continuing with the development of CFD methods – at that time multigrid methods were popular and parallel computing was emerging as a CFD topic. However, I was most fascinated by the contacts with industry, and Professor Durst created many such contacts.

The first industrial project I participated in was about the simulation of a slot coating process that was used by the company Hoechst (does not exist anymore) to coat photographic paper (nobody uses it anymore). Our simulation capabilities at that time were limited, but the greatest surprise for me came in the first meeting with engineers from Hoechst. They explained what the problem was: in Japan, the company Fuji (maybe someone remembers films for cameras made by Fuji) had a machine that was coating paper while it was moving at 1 m/s, while their new machine at that speed created poor coat quality, so they had to reduce the speed. I asked how they designed the new machine, and what kind of computations and simulations they did.

I had a great respect for German engineering and believed that everything “Made in Germany” was best in class; thus, I was surprised that Japanese engineers were doing a better job. To my great surprise, Hoechst engineers said that they had done no computations or simulations – the engineer who designed the old machine built also the new one, but for some reasons it was not working as expected… I was totally disappointed – the illusion of German engineering perfection disappeared like a soap bubble.

What Is The Value Of CFD ❓

From my point of view, CFD has two aspects: It is still a research discipline, because the methodology needs to be improved and extended to cover more application areas and the accuracy of solutions needs to be increased. Remember: in CFD, we produce approximate solutions – nothing is exact, and it is important to increase the accuracy and confidence in solutions.

On the other hand, CFD is a tool that engineers use alongside other tools to optimize designs or operating conditions for various devices affected by flow, heat transfer, and other related phenomena. The CFD market is growing with something between 10% and 20% per year, which shows that the industry is more and more recognizing its power and expanding its use.

Simulations in the field of structural mechanics were established earlier as a viable tool, in my opinion, because a large class of problems is governed by linear or weakly non-linear equations. In fluid flows, there are almost no linear problems of practical relevance (except for creeping flows at very small Reynolds number, like in porous media). Even laminar flows are non-linear, not to mention turbulence… The availability of affordable computers and the increased user-friendliness of CFD tools (especially the interface to CAD for geometry description and automation of grid generation) were important milestones for the spreading of CFD in all fields of engineering.

I recently attended the 9th Voith Hydrodynamics Symposium and was impressed by how successfully good engineers are using CFD to improve designs. Just one example: a new ferryboat, designed fully by CFD for one operator in Scotland, needs 40% less power but carries 40% more load than the existing ferryboat built 10 years ago! The company decided to give up the older ship (although it is still relatively new) and ordered immediately two more new ships…

Hard- and Soft Skills Vital To Your Job 🧩

The requirements are slightly different for CFD developments and for its application in engineering. In both cases, a solid knowledge of fluid mechanics, thermodynamics, and mathematics is very important – I consider these as essential hard skills.

The knowledge of broader physics is an advantage. On the soft side, I would rank teamwork, creativity, and intuition as the most important soft skills. Decision-making and time management are also relevant, mainly in the sense that it is important to decide what to do, how to do it, and in which order, as well as to decide when it is time to pull the break and seek help or give it up completely and start a new project.

In CFD development obviously, programming skills are important; you can program the same algorithm in many ways and always obtain the same result, but the codes will differ, depending on the programming style and skills of the programmer. It is important that the code is efficient, but it should also be easy to understand, maintain, and extend by others.

In application, in addition to theoretical hard skills, it is also helpful if you have some hands-on experience in the field.

Is Passion A Prerequisite For Success? 🔥

Discipline is important, but it is not enough. I believe that passion is essential whenever you want to perform above average – no matter in which business. You have to like what you are doing so much that you are prepared to make sacrifices and suffer, when necessary, like working longer hours, sleeping less, doing without other pleasures for a while…

The path to success is seldom straight and even – in most cases, there are obstacles, uphills, and downhills that you cannot master if you stick to regular working hours and go after your hobbies and other interests regardless… I tried not to neglect my family, but I certainly had to cut down on many activities that I would have loved doing due to a shortage of time.

What's More Important – Education, or Skills & Experience? 🧠

I’d say both are equally important. You need to be educated enough to understand what you are doing, otherwise it is difficult to develop effective skills and useful experience. Education offered by schools and universities is not always perfect, and every person consumes it differently. I never learned by heart and memorized formulas - I tried to understand the basic idea, the principles, the links between different ingredients… You can work out details yourself or with the help of books if you understand the underlying principles; books don’t help if you do not know what to look for and where to look for it.

Another ingredient that is important, but is difficult to develop, is intuition. Intuition based on knowledge helps you to quicker grasp the problem and pick the most promising path to solution out of many possibilities. If you ask 10 engineers to solve the same complicated problem, the fastest solution will come from the person with the best intuition.

Daily Habits ✔️

It may sound unreal, but I do not have steady daily habits (other than working if there is nothing else of higher priority that needs to be done). I usually get up between 6 and 7 o’clock and start working on whatever is on top of the list (sometimes I do make to-do lists).

An exception is spring and summer days, when I usually first do the garden inspection, looking for new flowers, checking how vegetables and fruit trees grow, listening to bees buzzing around flowers… My wife gets up a bit later, and then follows her habits first: one cup of coffee, another cup of coffee, and – very often – yet another cup of coffee, reading (online) newspapers in the meantime. We usually have breakfast around 10 am. Unless there are scheduled business meetings, my wife would decide what comes next (she has the highest priority): we often go shopping together, walk through the parks of Bad Reichenhall, or ride our bikes along the Salach River. Sometimes there are repairs to be done or something to be built; I have most of the tools that a mason, carpenter, plumber, painter, or electrician would need and seldom seek help from a professional craftsman. If nothing else needs to be done, I return to my study room and continue to work.

Occasionally I join my wife to watch television for an hour – usually, I am working from early evening to late at night every day, even on holidays, almost never going to sleep before 1 am. Urgent tasks may change the daily schedule completely…

While I was working full time, the routine was different: getting up, having a quick breakfast, driving to work, coming back home around 7 pm, working again from 9 pm to 1 am… I do not recommend anybody to adopt such daily habits, but I guess that most people who are successful in their job do have to work longer than the usual 8 hours a day…

Most Significant Success Factor on Your Journey 🚀

Other than wanting to be an engineer, my career did not develop according to a plan or desire; it was more influenced by unexpected events and actions by other people than by my intentions.

Upon finishing my PhD project in London, I returned to Sarajevo but soon realized that my CFD expertise would be of little value there: there were neither computing resources available, nor industry interested in CFD application. I contacted Dr Philip Jones at AVL in Graz, Austria, whom I met a few months earlier on my way from London to Sarajevo, and he invited me for a job interview. I started the journey with my wife by car, but a snowstorm stopped us at Zagreb – the highway was closed ahead of us, and we had to turn back.

Before a date for another meeting was scheduled, I traveled to London where I stayed one month to finish documentation for codes that I wrote during my PhD project, because Professor Gosman intended to have them used by other PhD students and postdocs. He offered me to stay as a postdoc and mentioned the intention to set up a company for a commercial CFD business, but I declined; neither my wife nor I were happy with our life in London – we agreed that we would prefer to live and work on the European mainland.

One evening I saw at an underground station in London a German newspaper “Süddeutsche Zeitung” on sale, and I took a copy out of curiosity. My German was not very good at that time, but when I saw in the ads section that a postdoc position in the field of CFD was open at the Chair for Fluid Mechanics at the University of Erlangen, I immediately wrote a letter (by hand) to announce my interest and sent it next morning. I intended to provide the required documents on return home, but as a coincidence, Dr. Georg Scheuerer, who was the leader of the CFD group in Erlangen and who posted the ad in the newspaper, came to visit Professor Hanjalić in Sarajevo just at that time. After we met and discussed my application, he said that I had the job! A few weeks later, we moved to Erlangen and I cancelled the visit to Graz.

A year later Professor Joel Ferziger from Stanford University received the Humboldt prize as a distinguished researcher and came to stay half a year at the Chair for Fluid Mechanics in Erlangen. We collaborated on multigrid methods and error estimation, and one day I made a joke by saying that we could write a book together about CFD. To my surprise, Joel said that it was a good idea and invited me to come to Stanford so that we could work on that project. I applied for a scholarship from the German Research Foundation and got it, so in autumn 1991 I went with the family to stay for a year in Palo Alto.

In the meantime, Professor George Raithby from the University of Waterloo, Canada, visited Erlangen and one evening he discussed with Dr. Georg Scheuerer and me over dinner the idea of setting up a German branch of the company Advanced Scientific Computing Ltd, which he and co-workers had set up in Canada to market the CFD code “Tascflow”. Georg had left the university a year ago and I had his position as a leader of the CFD group. We agreed that I should leave the university and move to the place where Georg lived; we would become minority shareholders of the new company and the money for the start would be provided by the mother company from Canada. It was only left that I discussed the plan with my wife.

After dinner, I stopped at my office and found on my desk a paper bag, without a message. I looked inside and found a pair of baby socks, size 0. I immediately figured out that my wife was there and left the bag for me; she was visiting a doctor and stopped by afterward. The socks meant that she was pregnant – we were to become parents for the second time… That night we discussed the plan and decided that I should better stay at university. The major reason was that, as foreign citizens, we had to apply for a stay permit every year, and the permit was granted on the condition that I work for a university; changing employer would require applying for a new permit. If I were to work for Siemens, that would probably not have been a problem, but a two-man start-up company does not sound like a secure employment. The authorities were always trying to avoid the risk that foreigners remain jobless and have to be supported by taxpayer’s money. The risk was high and with two small children, we figured out that security is better than adventure. The plan was realized without me – Georg Scheuerer was very successful with the new company…

In 1991, I met for the first time Steve MacDonald, President of Adapco Inc., the partner company of Computational Dynamics Ltd from London. The two companies were developing and marketing the CFD software STAR-CD. He offered me a job in his company in Melville, on Long Island, USA. The offer was very attractive: 78,000 $ per year initial salary, plus relocation costs… My income in Germany was less than half of that amount, but two items in the offer made us decide not to accept it: (i) only two weeks of holiday per year (in Germany we had 5 weeks, plus about 12 days of public holidays spread across the year), and (ii) the statement that, if I had any questions, I could call by phone at any day, someone was always there (my wife suspected that I would be one of those present in the company also on weekends)…

A few months before going to the USA, I received a letter from an unknown sender. In the envelope was only a cut-out from a newspaper ads section, containing the announcement that a professor position for fluid mechanics was open at the Institute of Shipbuilding, University of Hamburg. No message, nothing to indicate who sent the ad to me, other than the post stamp showing that the latter was posted in Karlsruhe, Germany. I never found out who sent it to me, and although I did not believe that I would get the position, I sent my application to Hamburg. A few weeks before leaving for the USA, I received an invitation from Hamburg to come and give a lecture – I was shortlisted among three candidates and thus had a chance to become a professor. When I returned from the USA a year later, a letter from the President of the University of Hamburg was waiting for me, offering me the professor position – which I immediately accepted. I worked as a professor at the Institute of Shipbuilding until the end of September 2001.

In 1999, Professor Brian Launder from the University of Manchester Institute of Science and Technology (UMIST) contacted me and asked whether I would be interested in taking up his position when he retires later that year. He invited me to come with my wife to Manchester and he spent two full days with me, showing me the university, the laboratories, and the city. As I was leaving, he asked me to let him know as soon as possible whether I really wanted to take the position or not; he knew that it was a custom among German professors to use an offer from another university to negotiate better conditions to stay at the old place, and I promised that I would not do that.

It was the greatest honor that I have received in my career. I would have loved to work in the lab where Osborne Reynolds worked, but unfortunately, neither my wife nor my kids were keen to relocate to Manchester. I too found the living conditions in Manchester less appealing than in Hamburg, but if I was a bachelor, I would have gone to Manchester regardless of that aspect. Thus, two days later I wrote back to Professor Launder and informed him about the decision. He thanked me for making the decision so quickly.

In 2001, I accepted the second offer from Steve MacDonald to leave the university and work full-time for CD-adapco at the company’s Nuremberg office, which I did until the end of 2013.

Thus, my career path was mostly laid down by other people, to whom I am deeply indebted. I had to make decisions at several crossroads, and I do not know whether another choice would have been better or worse. I never look back and question my decisions (I would do that only if it became obvious that the choice made was wrong – which fortunately has never happened). Once I make a decision, I stick to it and work hard to make the best out of it. The satisfaction comes when the results show that the choice was good (which has always been the case so far); the question of whether another option could have been even better never worried me.

What Inspired You to Become an Engineer? 🧑🔬

When I was 6 years old, my father brought two engineers to our house for dinner. We lived in a village, 20 km away from the nearest small town, without electricity or running water in the house. I had not seen town life yet. They talked about their work, but I did not understand that – all I memorized was that they were engineers. One of them took me on his lap, pulled a piece of paper and a pen from his handbag, and made two drawings which he then gave me. One was a car; the other was an airplane.

They looked like this:

I was overwhelmingly fascinated by that skill! My drawings hardly looked like what I wanted them to show, but these were just perfect! I had at that time never seen a car, other than in pictures in newspapers which my father used to bring when he occasionally went to the town. I often laid on my back in gras and watched airplanes in the sky, but I couldn't see details – and the drawing showed windows and doors…

I assumed that being able to make such drawings was an engineering skill, and because I wanted to acquire such skills, I decided that I shall be an engineer.

After primary school in our village, I moved to a small town to go to a secondary school – a technical school for mechanical engineering. Learning descriptive geometry did help me to make more realistic-looking drawings of things. However, to become an engineer one must go to university, and there I faced a problem of financial nature.

I decided to first look for a job as a technician in the nearest town and study engineering part-time, alongside work. I went to the job agency and declared that I was seeking work, but the clerk said that my certificate from the technical school had an error and needed to be corrected. I then went to the school in the other town and the administration was very helpful, produced quickly a new certificate but the problem was that the school director, who needed to sign it, was on holiday. They gave me his address and said that I should go and see whether he was at home – the chances were good because he was working on a book. Indeed, he was at home, and while signing the certificate, he asked me what I was going to study. I told him that I was short of money and intended to get a job first and study part-time. He took off his glasses, left aside the pen, asked me to sit down, and in the next 15 minutes tried to convince me to give up that plan, take a student loan, and go to study mechanical engineering as a regular student, no matter how hard it may initially be.

On the way home I decided to follow his advice, and so I enrolled to study mechanical engineering at the University of Sarajevo. There were several branches available, and I picked up “engines and motor vehicles”. My dream was to work on a ship and see the whole world…

The first two years of studies were common for all students of mechanical engineering. Before the third year started, two professors persuaded me to switch to the branch “power and process engineering”. My diploma project directed me toward CFD specialization, but I always declare myself as being an engineer – a child’s dream that turned into reality.

What Is The Most Challenging Project You've Worked On? 🏔️

A few years after I started working for CD-adapco, one of my former students, Bettar el Moctar (now a professor at the University of Duisburg, at that time working for Germanischer Lloyd in Hamburg) approached me and asked whether I could help to solve one problem. A new mega-yacht was exhibiting torsional vibrations at speeds around 16 – 18 knots; the shipyard had been trying to solve the problem for a year without success, and the owner was becoming nervous… The budget was exhausted, and the solution was needed quickly…

I had to think hard and run a few ideas through my head, and then my intuition suggested that what I had in mind could work. I was sure that vibrations were flow-induced, it was only not obvious at which part of the ship. There were bow thrusters, underwater exhausts, skeg, four shafts with one I and one V bracket, and a few other details of the geometry that could potentially lead to flow unsteadiness.

My hope was that we could identify the source of the problem without simulating fluid-structure interaction; after all, we do not want the ship to vibrate. We split the wetted surface of the hull and appendages into ca. 40 patches and organized them to compute pressure and shear forces on each patch and record them in time. We also defined many sensor points on the hull surface where we recorded pressure variation in time. The aim was to try to identify what induces the unsteadiness in a single URANS simulation on a grid with about 6 million control volumes; more than 20 years ago, it was a reasonably fine grid for our computing resources.

After the simulation was done, we analyzed the recorded data and indeed identified regions on the hull where the flow was fluctuating (with a kind of von Karman vortex shedding) with a frequency similar to the frequency of hull vibration. Fortunately, once the origin was visible, so was the solution: a kind of splitter plate that prevents the interaction of unavoidable vortices on either side of it. Another simulation had to be done with a modified geometry, and it showed a smooth flow where earlier shedding was observed.

The results were delivered, and we moved on to other challenges. A few months later I received a phone call from Bettar one evening, around 10 pm: he wanted to tell me that the suggested remedy had been implemented, and on that day, they conducted sea trials and could not identify any vibration at all! That phone call meant a lot to me – it recharged all my batteries to sustain the inevitable troubles in other challenges ahead of me.

How Do You Stay Current With The Latest Developments And Trends In CFD? 💡

Unfortunately, I am not current with the latest developments and trends at all. I’ve always been short of time and therefore I was looking for information about what others were doing only when I had to; whenever I had my own ideas, I followed them first. That is not what I would advise others to do – it is important to know what is already available. I have several times rediscovered things that I had discovered earlier but forgot about it and did not bother to check. Don’t do that: before starting any new task, check whether someone has already done it.

Nowadays, you can find almost all information on internet. At the time when my habits were created, the internet did not exist: I had to go to library to search for sources of information, and that was a tedious and time-consuming task. I also suggest not to rely blindly on AI, because you cannot (yet) be sure that it is telling you the truth. Use search engines and then judge yourself which one out of many suggestions might be correct for you. Published papers can also contain wrong information. I twice complained about it to journal editors; in one case, I had to write a paper with correct solutions, and in the other – because the wrong content was brought to my attention while only an online version was published – the editor managed to prevent printing and remove the online publication.

One Science Concept That Engineers Commonly Misunderstand? 🚫

Combining theoretical knowledge with numerical or experimental analysis to obtain an answer with sufficient accuracy as fast as possible, with minimal effort – this is what engineers should be striving to achieve. I have seen people doing three-dimensional CFD analysis of flows when they needed information which is available in diagrams found in most textbooks.

People who sell CFD software like such engineers, but that is irresponsible; one should always use the tool that is least complex for a given task. If diagrams and formulas contain the information that you seek, check them first. If one-dimensional analysis is good enough, don’t do three-dimensional simulations.

Where Do You See The CFD Industry Going in the Future? 🧪

I believe, without any doubt, that CFD will continue to spread across all industries, both in the short and in the long term. There are still too many products that are built without a proper analysis, and CFD can help to optimize everything, from the shape of bends in water pipes to sophisticated products like cars, ships, trains, and airplanes. I believe that CFD could easily help to reduce the energy consumption of modern societies by more than 20 %; with a little bit more effort, much higher savings are possible.

For many tasks, current CFD capabilities are sufficient. However, I expect further improvements in several aspects. One is the increase in efficiency by using GPUs. CFD will profit from huge investments in computing technology because of the AI hype, as it profited in the past from CPU development driven by the gaming industry. The software requires substantial optimization and restructuring to benefit from this trend.

I also expect that transient simulations of LES-type will see increased use in the industry because in complex geometries statistically steady flows are the exception rather than the rule. Simulation of complete systems (e.g., ship hull + rotating propeller + rudder + other appendages underwater + Fletner rotors or sails + wind over superstructure, etc.) will have to be run in full scale and then we need wall functions for LES because we cannot afford to resolve the near-wall zone. All components of CFD tools can be further improved, and it is not impossible that novel methods immerge…

The future is bright and exciting for CFD, and I’ll certainly follow the developments in my retirement phase and try to contribute, one way or the other…