Introduction

In the rapidly evolving landscape and dynamic realm of manufacturing, it is imperative for businesses to stay ahead by seizing and utilizing advanced technology. Enterprise Resource Planning (ERP) software is pivotal in streamlining operations, improving productivity, and enhancing overall efficiency across many industries.

With a wide array of business intelligence and financial management options, choosing the right manufacturing ERP software solution can be challenging.

ERP Solutions for Manufacturing

This blog will compare seven popular ERP software solutions for the manufacturing process:

Let's dive into the details of on-premises and cloud-based manufacturing process software and explore the unique features and capabilities of manufacturing software for each various cloud manufacturing software system.

StartProto

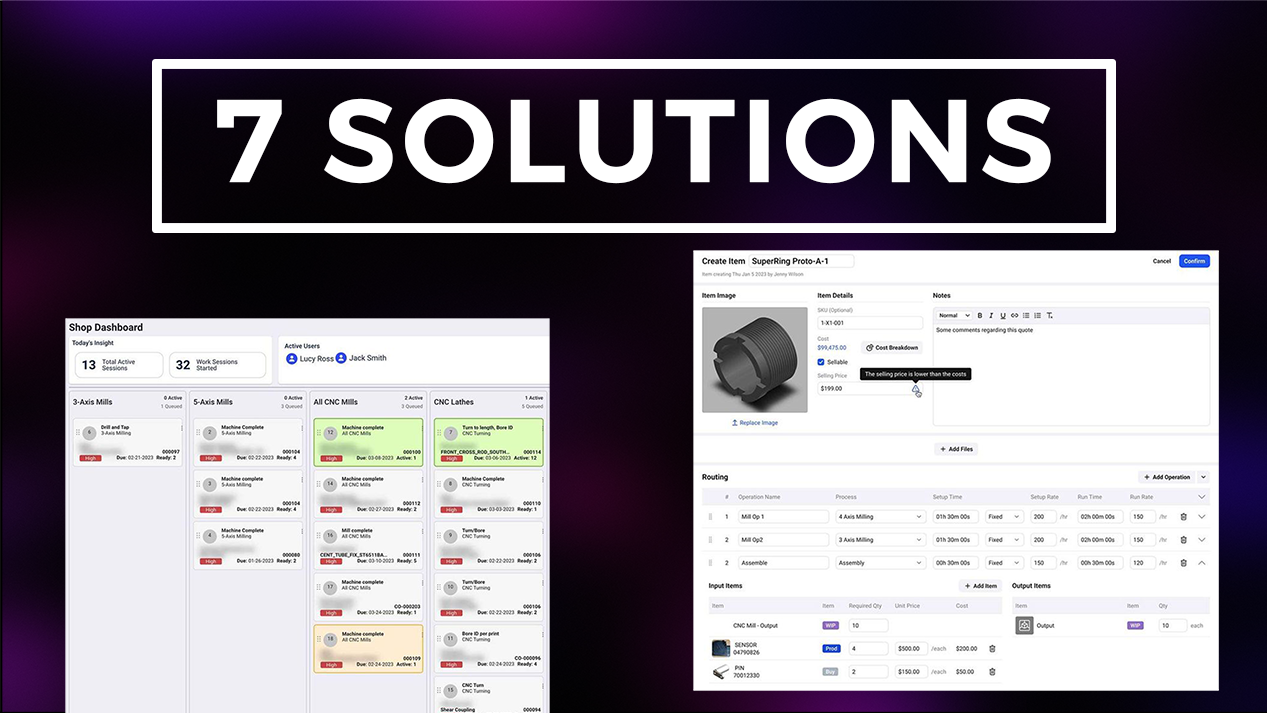

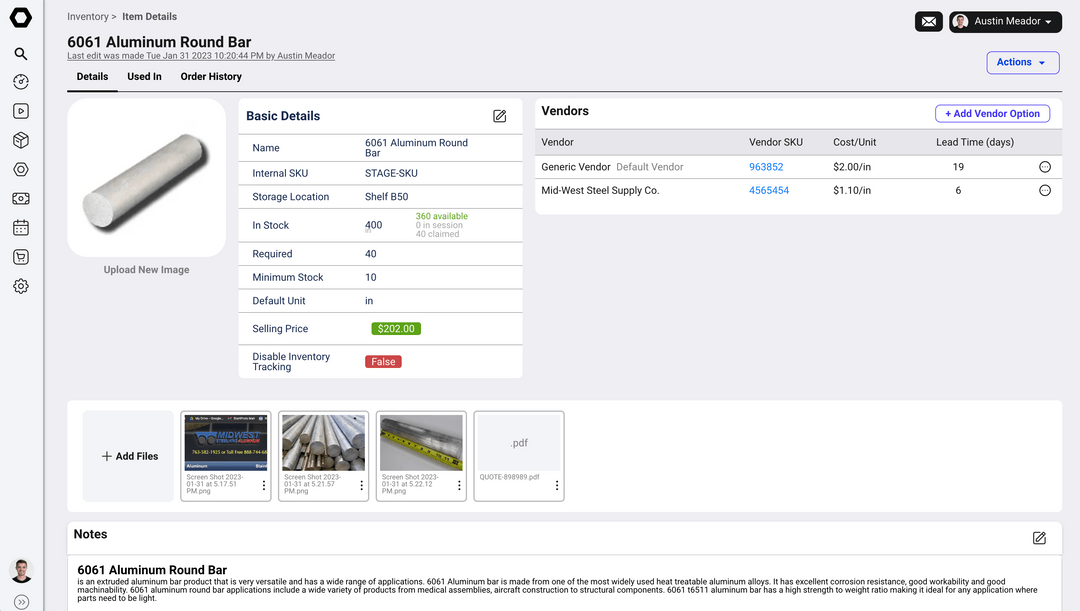

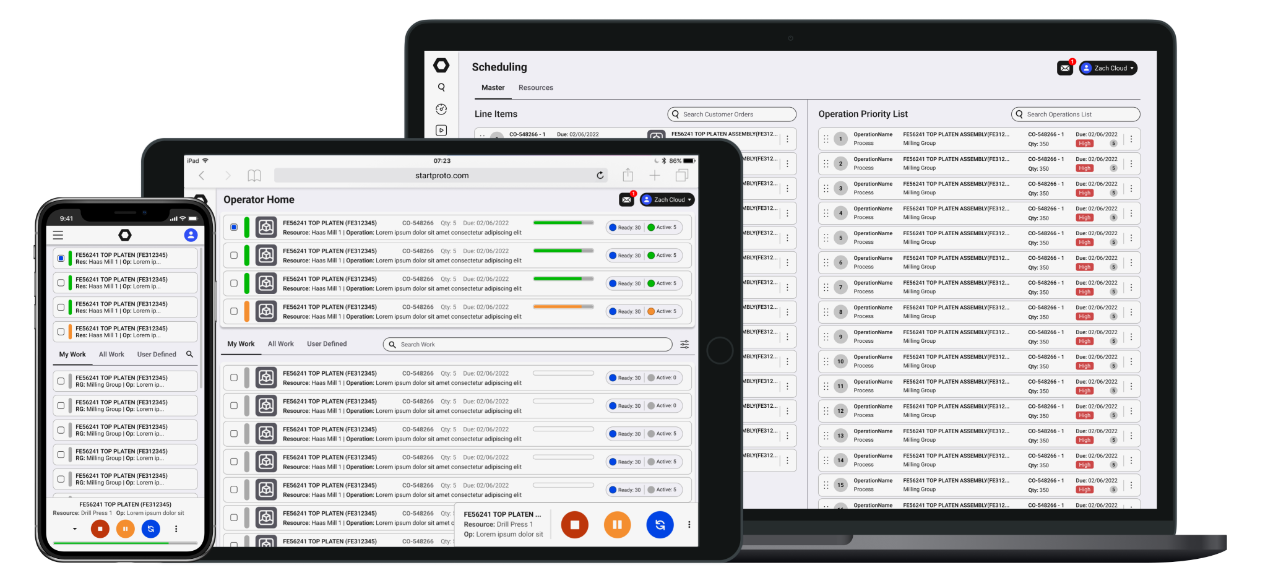

StartProto is an ERP software solution designed specifically for small and medium-sized manufacturing businesses. It offers a user-friendly interface and focuses on core functionalities of manufacturing software, such as inventory management, production scheduling and planning, and order tracking. By leveraging StartProto, manufacturers can elevate their operations to new heights, adapt to changing market dynamics, and ultimately achieve sustainable growth and success in the ever-evolving manufacturing landscape.

StartProto Advantages:

StartProto's key strengths lie in its affordability and ease of implementation, making it an ideal choice for companies with limited resources. StartProto offers robust reporting and analytics capabilities that empower manufacturers to gain valuable insights into their operations. The system generates detailed reports and analytics on key performance indicators (KPIs), such as production output, equipment utilization, lead times, and inventory levels.

By analyzing these metrics, manufacturers can identify bottlenecks, pinpoint areas for improvement, and implement data-backed strategies to enhance performance and competitiveness. StartProto's reporting capabilities also enable manufacturers to meet regulatory compliance requirements by maintaining accurate records and ensuring traceability throughout manufacturing.

StartProto Disadvantages:

However, it may lack some advanced business features required by larger enterprises as well as accounting.

ProShop ERP

ProShop ERP is a comprehensive manufacturing management system that covers a wide range of functionalities. It excels in business processes, business intelligence, job scheduling, shop floor control, and quality management.

ProShop ERP Advantages:

ProShop's intuitive interface and ability to integrate with various CAD/CAM software make it a preferred choice for companies involved in complex manufacturing processes. Its strength lies in its own cloud-based software and its ability to provide real-time data and insights, real-time historical data and also real-time data analysis, and both historical data and real-time data analysis, enabling businesses to make informed decisions.

ProShop ERP Disadvantages:

ProShop ERP, like any software solution, may have some disadvantages for manufacturers. One potential drawback is the initial implementation and setup process. Another disadvantage of ProShop ERP for manufacturing and manufacturers may be the learning curve associated with the software. ERP systems are typically robust and feature-rich, meaning users need to invest time and effort to become proficient in using them effectively.

JobBOSS 2

JobBOSS 2 is a comprehensive ERP solution tailored for small to mid-sized job shops. It offers many features, including estimating, quoting, order and project management, scheduling, project management, inventory control, and shop floor tracking.

JobBOSS 2 Advantages:

JobBOSS 2 also provides detailed reports and analytics to help you monitor your company and performance and identify areas for improvement. Its strength lies in its ability to handle complex accounting and job costing, which is crucial to accurately track costs, sales, and profitability

JobBOSS 2 Disadvantages:

However, some users may find the interface slightly outdated and need a modern facelift. Another point of contention is that JobBoss and many of the E2/M1 products are owned by a private equity firm, a notable concern among the user base. JobBOSS, along with many E2/M1 products, is managed by a private equity firm, whose primary objective may be perceived as maximizing revenue extraction from their software portfolio. This has led to the reduction in the commitment towards customer service and support for ECI-owned software.

Katana MRP

Katana MRP is a cloud-based, cloud-manufacturing software manufacturing ERP software system aimed at small businesses and e-commerce manufacturers. It specializes in inventory management, production scheduling, sales order management, and fulfillment planning.

Katana Advantages:

Katana MRP's unique strength lies in the cloud-based software and the cloud and its seamless integration with popular cloud e-commerce platforms such as Shopify and WooCommerce. It provides real-time inventory, demand, and sales data and helps optimize all production processes and workflows, making it an excellent cloud-based software choice for businesses with online sales channels.

Katana Disadvantages:

While Katana excels at more jobs and inventory and warehouse management for more jobs, it may lack some of the more advanced features needed by larger job shops with more jobs, complex workflows, and more warehouse management and inventory management.

Global Shop Solutions

Global Shop Solutions offers a comprehensive manufacturing ERP software solution for manufacturers of raw materials and finished goods of all sizes. It covers various areas, including accounting, inventory control, scheduling, and customer relationship management (CRM).

Global Shop Solutions Advantages:

Global Shop Solutions stands out in the industry with its ability to cater to different manufacturing operations, raw materials, and business processes, from warehouse management and discrete part manufacturing companies to process manufacturing industries. Its flexibility and customization options suit large enterprises, manufacturers, small manufacturers, and businesses with unique production requirements.

Global Shop Solutions Disadvantages:

However, Global Shop Solutions' extensive functionality may also make it more complex to implement and use, requiring adequate training and support. One of the main criticisms directed at GSS pertains to its overall inefficiency. Users have reported that the ERP system tends to slow down productivity rather than enhance it, leading to an increased workload. This inefficiency, ironically, creates the need for additional staff to manage the extra work created by the system, which directly opposes the core purpose of an ERP system: to streamline and simplify operations.

Another significant drawback lies in GSS's customer service. Feedback indicates a lack of communication and support from the GSS team, exacerbating existing frustrations. Users report being left without responses or solutions to their issues, which shows a disappointing lack of follow-through from the support team.

The system's inefficiencies become particularly apparent in the accounting department. Tasks that should be straightforward, such as deleting invoices, become a time-consuming endeavor. This complicates everyday processes and significantly reduces the speed and efficiency of the accounting team.

GeniusERP

Genius ERP is a cloud-based manufacturing ERP software solution specifically designed for small to mid-sized manufacturers. It focuses on production planning, material requirements planning (MRP), and quality control.

Genius ERP advantages:

Genius ERP provides an intuitive interface, making it easy to use for businesses transitioning from manual or spreadsheet-based systems.

Genius ERP Disadvantages:

However, Genius ERP may have limited scalability for larger enterprises and manufacturing companies with complex purchase orders, part manufacturing operations, sales orders, and supply chain and demand chain operations.

Fulcrum Pro

Fulcrum Pro is an ERP software solution for manufacturing businesses seeking a comprehensive system to manage their operations. It encompasses various modules, including inventory management system, supply chain management, production planning, work order management, purchasing, and accounting and financial management.

Fulcrum Advantages:

Fulcrum Pro's notable strength lies in its robust data analytics and reporting capabilities, allowing businesses to mine data to gain actionable business insights and optimize business processes further.

Fulcrum Disadvantages:

One potential disadvantage is the software's lack of comprehensive browser-based ERP functionalities specifically tailored for manufacturing and production processes. While Fulcrum offers data collection and workflow management tools, it may not provide the advanced features and integrations necessary for complex manufacturing operations, such as production planning, inventory management, or supply chain optimization. Manufacturers looking for a complete ERP solution may find Fulcrum's capabilities limited in meeting their specific industry requirements, which may require them to seek additional software or customizations to fill the gaps.

Conclusion: ERP Software Solution Considerations for Manufacturing

For decision-makers, choosing the right manufacturing ERP software solution for their own manufacturing company or business is a critical decision-making move that can significantly impact your operations and productivity.

Each of the seven cloud ERPs and solutions discussed—StartProto, ProShop ERP, JobBOSS 2, Katana MRP, Global Shop Solutions, GeniusERP, and Fulcrum Pro—offers unique features, functionality, and strengths tailored to specific industries and business requirements.

When evaluating ERP system options, consider your business processes, production processes, size, complexity, industry, and specific needs. Thoroughly assess each solution's functionalities, scalability, integration capabilities, user-friendliness, and customer support before deciding.

Successful project management and implementation depend on thorough research, understanding your company and shop floor's workflow, and involving key stakeholders in decision-making. Take advantage of free trials, demos, and customer reviews to assess how each new ERP system or software aligns with your business goals.

With the right manufacturing ERP system and software in place, you can streamline your work in a process manufacturing company and your shop floor operations, optimize resource allocation, make cost savings, cut costs, make production schedule, and unlock new levels of efficiency for your job shop floor manufacturing operations.

Ultimately, the best manufacturing ERP system and software for your manufacturing business will be the one that aligns with your goals and empowers your organization to achieve greater efficiency, sales, profitability, and growth.

Why not try the only free ERP solution for manufacturing on the market today?

If you’d like to see more blogs on engineering solutions, consider subscribing to my blog or YouTube - and feel free to leave a comment down below! 🙂

Keep engineering your mind! ❤️

Jousef